PET Plastic Bottle Recycling Machine Application Areas:

Plastic bottle recycling machine is used for recycling bottle jars and other containers made of PET that can be collected and recycled into a wealth of products. PET can be recycled into new PET bottles and containers, carpet and clothing, industrial strapping, rope, upholstery fabrics, boat sails, automotive parts, fiberfill for winter jackets and sleeping bags, construction materials, and many other items.

Main Features:

1. High automatic level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing pet bottle flakes capacity: 300-3500kg/hr

2. Friendly control system (PLC integrated & separated control on each machine) , easy operation, monitor and emergency stop.

3. All parts of the pet bottler recycling machine contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes.

4. Ideal impurity removal effect. Here is from our customer's feedback.

1) Moisture: Max. 1-2%

2) Bulk density: 0.3G/CM3

3) Total impurity: 320ppm

A-PVC content: 100-300ppm

B-Metal content: 20ppm

C-PE/PP content: 200ppm

4) Particle size: 10-16mm(customized)

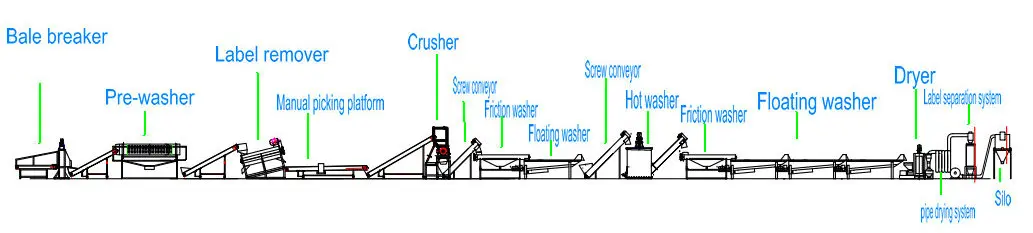

Machine list

Product capacity | 300kg/h | 500kg/h | 1000kg/h | 1500kg/h |

Workshop(L*W*H) | 40m*7.5m*6m | 42m*10m*6m | 70m*12m*6m | 75m*15m*6m |

Needed worker | 3-4 persons | 5-6persons | 7-8persons | 10-12persons |

Water supply (recycle use) | 2-3ton/h | 3-5ton/h | 7-10ton/h | 10-15ton/h |

Final product | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 10-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 100-320ppm | |||

Machine photos:

Final flakes photos:

Models&specifications:

Model | KDS-500 | KDS-1000 | KDS-1500 | KDS-2000 | KDS-3000 |

Capacity(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

Installation Power (kw) | 150 | 250 | 300 | 400 | 500 |

Labor | 2-4 person | 3-5 person | 5-6 person | 6-8 person | 8-12 person |

Final PET products quality for reference:

Final Moisture of PET flakes: < 1-2%

Total Impurity: < 200ppm

PVC Content: < 100ppm

PE/PP Content: < 200ppm

Particle Size: < 14-16mm

Final products real quality data is up to the real material situation,too.

Machine line Features :

1.Capacity: 300—3000kg per hour

2.Cap &Label separate with the PET bottle flakes automatically

3.Easy to operate, Full automatic.

4.Washing machine Parts which contact material use SUS304 with high thickness to ensure long service lift time

5.Bottle Types: PET Bottle, Plastic Bucket, Water Bottle, Coke Bottle,

6. Application: PET Strap, PET Yarn Fiber, PET Sheet,PET granulas

7. The whole production line with CE , ISO9001 certification